Warehouse lighting based on video analytics systems

Russia, Tver

task

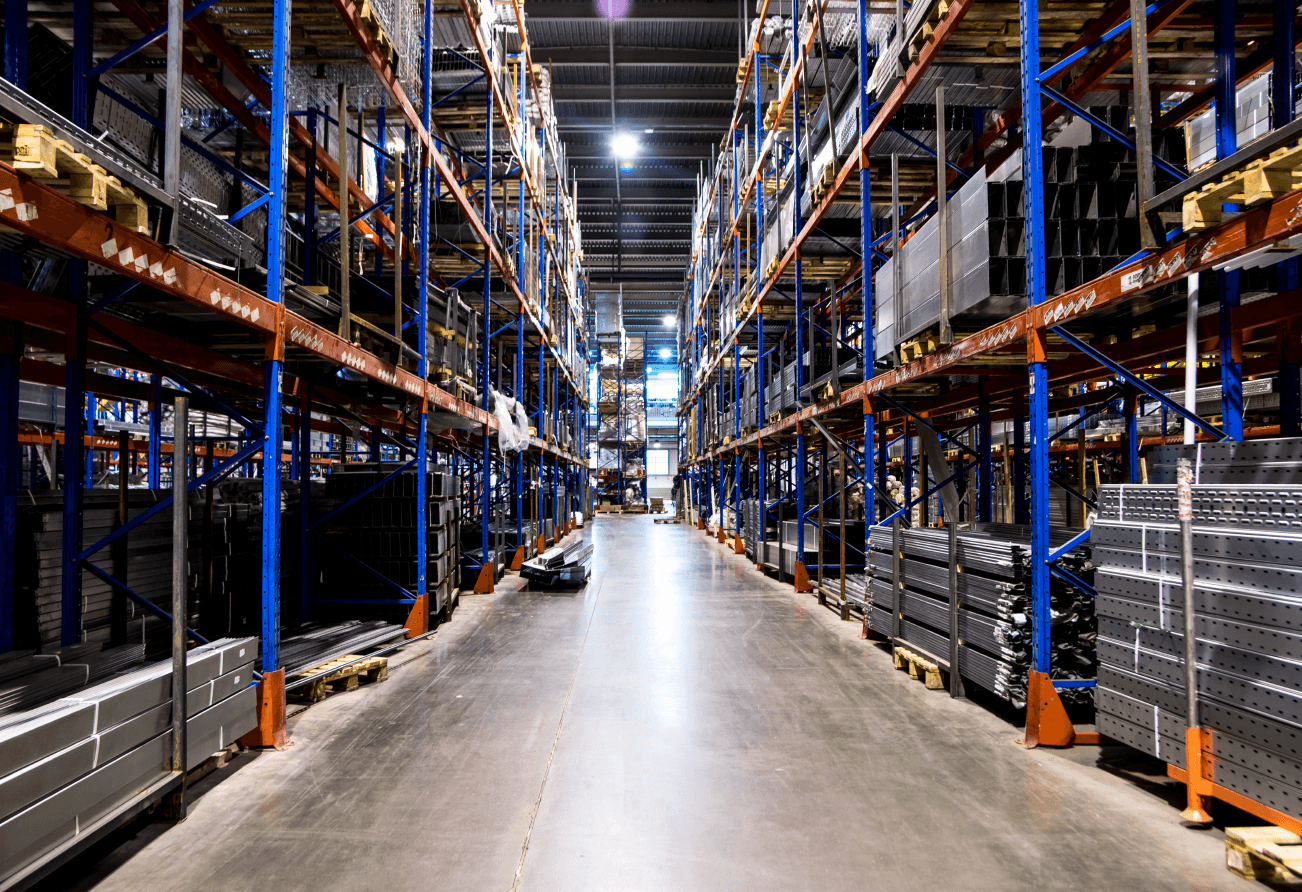

The plan was to replace old 400 W metal halogen lamps on 24 bays of the central warehouse complex in Tver with modern HB LED 150 lamps manufactured by Lighting Technologies. To achieve maximum savings, a control system was required that would turn LED lights on and off (dimming was not needed due to the lack of natural light sources) depending on the movement in the span, and, at first glance, the use of PIR sensors seemed obvious.For a span of 45 m, six High Bay PIR sensors were required with an installation height of 12 m. Having received negative results from testing a number of High Bay sensors, the coordinated decision was made to abandon this approach and try out a lighting control system that was then being developed based on IP cameras and video analytics module.

solution

Project implementationDeus developed a video analytics module and a special interface in the ME6 platform, which allows to:- Create the required number of detection zones (of any shape) in the camera's field of view;- Bind lighting groups to created zones;- Determine the number of moving objects in the frame;- Determine the trajectory of moving objects;- Create scenarios for the operation of lighting groups depending on the trajectory of the object (s).Project resultsFor two months of operation of the system, the solution:- Reduced energy costs by 50%;- Increased the life of the lighting installation by two times;- When using a control system for 24 warehouse bays, the payback period for a complex solution will be less than 2-3 years.In addition to economic indicators, the system allows to obtain analytical data on the workload of a particular zone in the form of graphs or visualize it in the form of heat maps, which will further optimize work processes in the warehouse.