enrichment and processing

features and approaches to lighting

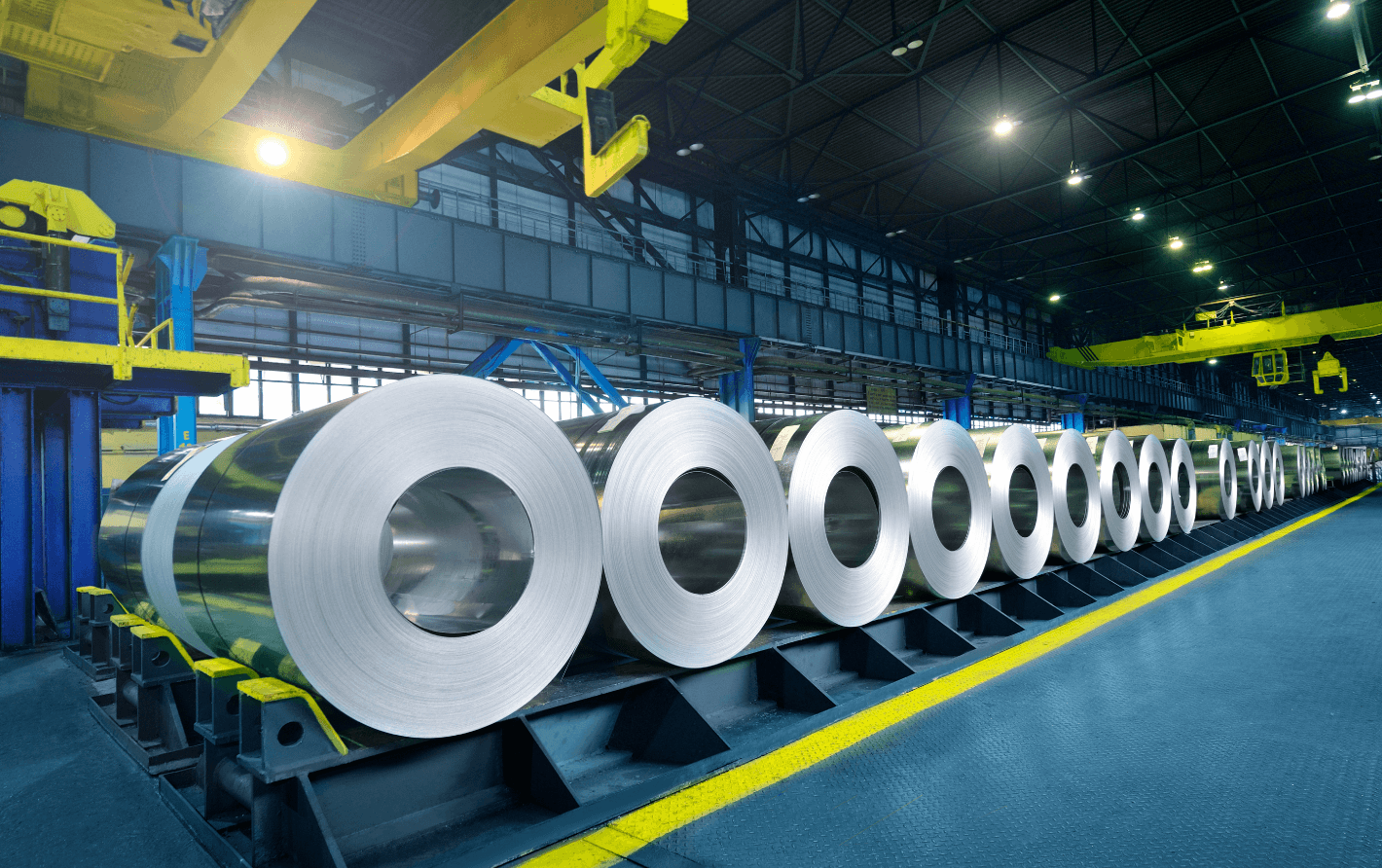

Properly designed natural and artificial lighting at metallurgical enterprises, including emergency lighting, is the key to efficiency, manufacturability and safety at the facility. high-quality lighting increases the productivity of work operations, ensures an uninterrupted and safe production process.

The choice of lighting and power supply devices must be approached taking into account the conditions of the operating environment.

Metallurgical enterprises, especially full-cycle plants, are huge production areas, including workshops with various technological processes. As a rule, production sites

metallurgical enterprises are characterized by high ceilings (up to 30 m), while the lighting equipment is fastened to the supporting trusses using a lyre, a bracket or a cable suspension. Luminaires used in these structures must be highly efficient and provide the required level of illumination on the rationing surface. If it is necessary to increase the level of illumination in local areas of workshops, portable lighting devices and crane lighting should be provided. Luminaires used for crane lighting must not only meet the general requirements of mechanical and climatic protection, but also be resistant to increased vibration loads.

Requirements for lighting installations may vary due to a variety of technological processes and features of the operating environment. For example, metallurgical enterprises are characterized by the presence

powerful melting equipment. Molten metal, slag and sinter are sources of intense heat release. Ambient temperature at the top of the room - just where

lighting equipment is installed, - can reach critical values. Therefore, the lamps used in such workshops must work properly in the high temperature range.

Another important factor characterizing the production environment of metallurgical enterprises is active dust formation, especially in blast furnace and converter shops and in charge preparation areas.

In view of the conditions described, lighting equipment must have a high degree of protection against dust and moisture and be easy to use (regular cleaning of lighting fixtures).

In some cases, the processes of processing and enrichment of metals may be accompanied by the release of gases or the formation of explosive dust compounds (for example, the process of crushing metals). Luminaires used in such production areas must be resistant to chemically aggressive environments and meet the requirements of fire and explosion safety in accordance with the placement category.

The choice of lighting and power supply devices must be approached taking into account the conditions of the operating environment.

Metallurgical enterprises, especially full-cycle plants, are huge production areas, including workshops with various technological processes. As a rule, production sites

metallurgical enterprises are characterized by high ceilings (up to 30 m), while the lighting equipment is fastened to the supporting trusses using a lyre, a bracket or a cable suspension. Luminaires used in these structures must be highly efficient and provide the required level of illumination on the rationing surface. If it is necessary to increase the level of illumination in local areas of workshops, portable lighting devices and crane lighting should be provided. Luminaires used for crane lighting must not only meet the general requirements of mechanical and climatic protection, but also be resistant to increased vibration loads.

Requirements for lighting installations may vary due to a variety of technological processes and features of the operating environment. For example, metallurgical enterprises are characterized by the presence

powerful melting equipment. Molten metal, slag and sinter are sources of intense heat release. Ambient temperature at the top of the room - just where

lighting equipment is installed, - can reach critical values. Therefore, the lamps used in such workshops must work properly in the high temperature range.

Another important factor characterizing the production environment of metallurgical enterprises is active dust formation, especially in blast furnace and converter shops and in charge preparation areas.

In view of the conditions described, lighting equipment must have a high degree of protection against dust and moisture and be easy to use (regular cleaning of lighting fixtures).

In some cases, the processes of processing and enrichment of metals may be accompanied by the release of gases or the formation of explosive dust compounds (for example, the process of crushing metals). Luminaires used in such production areas must be resistant to chemically aggressive environments and meet the requirements of fire and explosion safety in accordance with the placement category.

we will help you solve your problem