machine tool industry

features and approaches to lighting

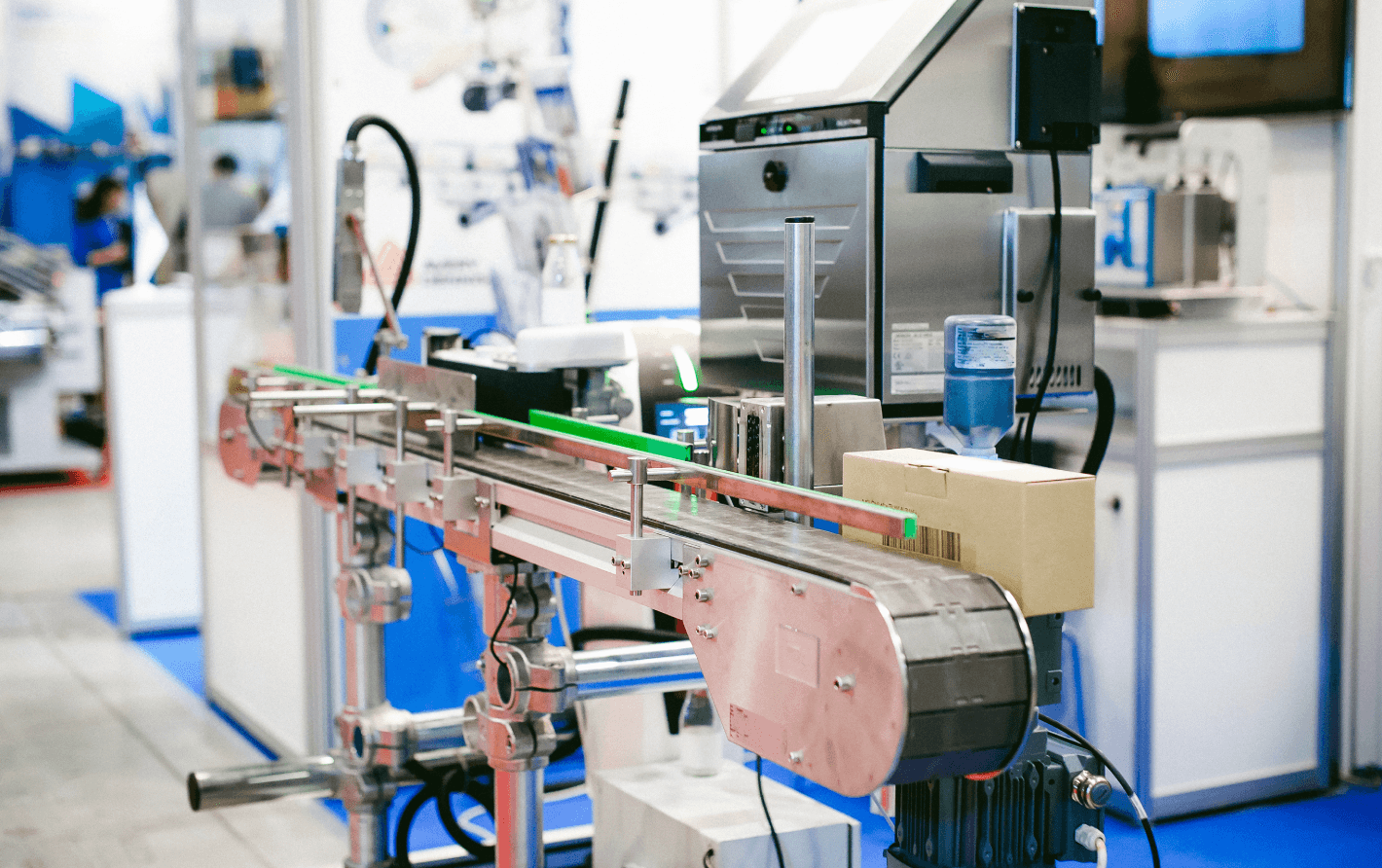

Machine tool industry specializes in the production of machine tools for various materials, performing turning, drilling, grinding, polishing, finishing, gear and thread processing, milling and various auxiliary operations.

The key factors influencing the development of the machine tool industry are ensuring the manufacturability of production, improving energy efficiency and introducing innovative technologies. These processes should affect all levels of the organization of the production process, including the features of lighting enterprises.

Previously, fixtures with mercury, fluorescent and metal halide lamps were used as main lighting devices for machine-tool factories. Lighting devices were mounted on a lyre or suspension. Such a lighting installation turned out to be energy-intensive and expensive to maintain.

Today, with the advent of energy-efficient LED solutions, it is possible to achieve unconditional compliance with all lighting requirements while significantly reducing energy consumption and maintenance costs

lighting installation.

The production process of machine tools includes the casting of beds and their machining in the blank shops, the manufacture of the main machine units in the processing shops, the installation and assembly of the machines in the assembly shops. Thus, the type of lighting installation and lighting fixtures should be selected based on the operating conditions. In particular, in the casting rooms of the beds, the process of obtaining blanks is accompanied by the release of heat from the melt, castings, as well as the formation of water vapor during the cooling of hot molds. For normal operation in the conditions described, lighting equipment must work stably at elevated temperatures, and also have a high degree of protection against dust and moisture.

The key factors influencing the development of the machine tool industry are ensuring the manufacturability of production, improving energy efficiency and introducing innovative technologies. These processes should affect all levels of the organization of the production process, including the features of lighting enterprises.

Previously, fixtures with mercury, fluorescent and metal halide lamps were used as main lighting devices for machine-tool factories. Lighting devices were mounted on a lyre or suspension. Such a lighting installation turned out to be energy-intensive and expensive to maintain.

Today, with the advent of energy-efficient LED solutions, it is possible to achieve unconditional compliance with all lighting requirements while significantly reducing energy consumption and maintenance costs

lighting installation.

The production process of machine tools includes the casting of beds and their machining in the blank shops, the manufacture of the main machine units in the processing shops, the installation and assembly of the machines in the assembly shops. Thus, the type of lighting installation and lighting fixtures should be selected based on the operating conditions. In particular, in the casting rooms of the beds, the process of obtaining blanks is accompanied by the release of heat from the melt, castings, as well as the formation of water vapor during the cooling of hot molds. For normal operation in the conditions described, lighting equipment must work stably at elevated temperatures, and also have a high degree of protection against dust and moisture.

we will help you solve your problem